We've all seen it in pro shops and online. Modern ice & roller hockey sticks range in price from somewhere in the $350-$400 range on down to about $60. Of course, there are still wood sticks out there which tend to be very inexpensive, but unless you're playing on a pond or a street, you won't want to seriously consider one as they just don’t perform anywhere near as well as composite sticks. So, what's the difference in all these hockey sticks? Which ones do the pros use? Why would a brand have four or five different stick prices to choose from? Isn't any composite hockey stick just about the same?

The answer is, perhaps obviously, they are not all the same aside from the fact that they all will allow you to play hockey with them. Here's what makes them unique.

Materials

Composite hockey sticks are constructed of a combination of four basic things: Carbon fiber and/or fiberglass, resin, and foam.

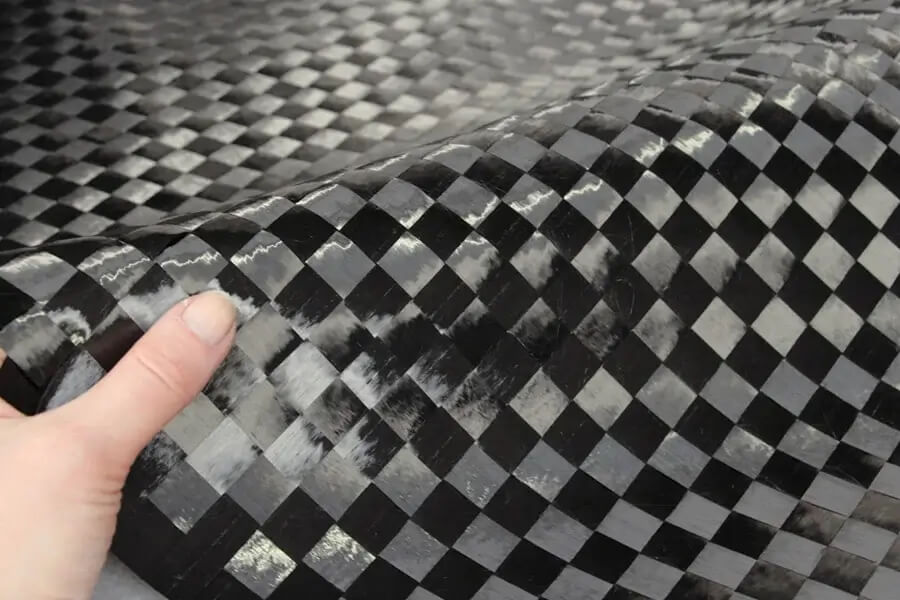

Carbon Fiber

Carbon Fiber is the lightest and most responsive of acceptable core materials used for hockey stick construction. It comes in varying width spread tow sheets that get layered together during manufacturing to form the body of the stick. The sheets are available in different strength fibers with the highest strength carrying the highest price tag. The leading manufacturer of carbon fiber for hockey stick construction globally is Toray Carbon Fibers out of Tokyo, Japan. Even if a stick says Minimus, TeXtreme, or some other label on the carbon, it’s nearly assured that it is composed of Toray carbon fiber at its core. Toray’s weaved carbon fibers are used as unidirectional (UD) tapes as well as used in very thin 3k, 12k, 14k, and 18k weaved fabric sheets in stick construction. In general, the larger the k in the weave (The larger square appearance) the thinner the sheets can be produced for a given strength.

Fiberglass

Fiberglass sheets are also used in hockey stick construction. The cost of fiberglass is less than carbon, it’s thicker and weighs more than carbon, and is generally accepted to be more durable to blunt impact than carbon fiber in side-by-side comparisons. It is usually reserved for lower priced stick construction because of the above characteristics and its increased durability.

Resin

Resin is the hardened adhesive that holds the layers of carbon fiber and/or fiberglass together. It adds weight and no performance to the stick, but is a necessity to hold it all together.

Foam

Foam is used in player sticks for the blade core only. It comes in different densities which results in a stiffer or softer feeling blade. In goalie sticks, foam is also used for dampening the paddle just as it does for the blade.

Construction

Blade and shaft are manufactured and assembled in varying ways, yielding a one piece stick.

True One-piece

The shaft and blade are assembled together from the start of the build. Provides the best feel and performance but incurs the most time and increases cost.

Spear Construction

The shaft is inserted spear-style into the blade during manufacturing to reach near the blade heel internally. Both are finished together to yield a high performing one piece stick.

Fused Construction

The shaft and blade are manufactured separately, then fused together in a fashion similar to how old two piece hockey sticks were made. Inexpensive to produce, but lower performance than the previous one piece styles and tend to feel blade heavy.

Putting it all together

The best performance in hockey stick manufacturing is achieved by alternating directional placement of the most layers of the strongest carbon fabric possible in a true one-piece build, while using the least amount of resin. This is where the thinnest possible carbon fiber fabric weaves yield the best results as they are flatter and require less epoxy between layers. Less epoxy equals less weight and more carbon to increase stick performance.

Layman's terms

- Elite & pro stock sticks = true one-piece construction with more of the highest strength carbon layers and less resin = Lightest stick with maximum performance (Weight of 400 grams or less)

- Then working backward in price points, you will begin with spear construction and move down to fused. You will find less carbon, lower strength carbon, and more resin in each stick, thus increasing the overall weight. The lowest price tiers also introduce more and more fiberglass layers to the build.